In the world of machining and fabrication, precision is the name of the game. When it comes to cutting, shaping, and forming materials, one indispensable tool stands out—the سنبه mandrel. This unassuming yet versatile device is the unsung hero behind many of the complex shapes and designs we encounter in everyday life.

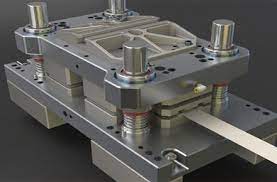

At its core, a cutting mandrel is a cylindrical tool that serves as the backbone for various cutting processes. It’s a critical component in the world of manufacturing, particularly in industries like automotive, aerospace, and metalworking. Its design may seem straightforward, but the applications it enables are anything but simple.

The cutting mandrel is typically made from durable materials such as high-speed steel, carbide, or diamond-coated materials. This choice of materials ensures longevity and precision, allowing it to withstand the rigors of continuous use. Its cylindrical shape may vary in diameter, depending on the specific task at hand, and it can be equipped with a variety of cutting tools, such as abrasive wheels, grinding stones, or diamond-tipped blades.

One of the key advantages of using a cutting mandrel is its ability to create complex shapes with unmatched precision. Whether it’s cutting intricate patterns in metal, shaping composite materials, or grinding down imperfections, the cutting mandrel excels in delivering the desired results. Its cylindrical design allows for controlled and uniform material removal, ensuring consistent quality across the workpiece.

More Stories

The Phenomenon of Fake Taxis: An Exploration of the Trend

라오스 여행: 숨겨진 보물 같은 매력을 찾아서

Understanding the Real Estate Market: Trends, Tips, and Future Prospects